- English

- فارسی

Coating and Cladding with Welding Technologies

In this subject we have focused on the formation of a layer of dissimilar metals on the surface of metallic substrate to improve various properties such as wear and corrosion resistance. There are many technologies available to do this (e.g., laser cladding, arc welding, thermal spraying, cold spray, etc.). Here are some example of project in this area in my research group:

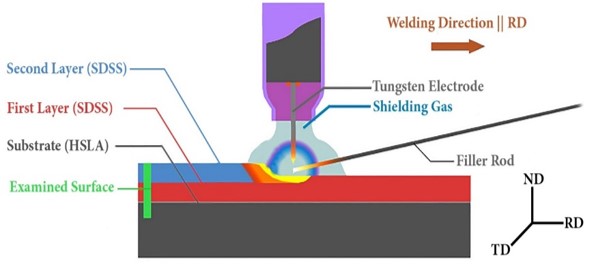

- Evaluation of microstructure and texture across the welded interface of super duplex stainless steel and high strength low alloy steel

- Effect of pulse current on microstructure and wear resistance of Stellite6/tungsten carbide claddings produced by tungsten inert gas process

- Microstructure and wear behavior of satellite 6 cladding on 17-4 PH stainless steel

- Optimization of pulsed TIG cladding process of stellite alloy on carbon steel using RSM

- Cladding of Stellite composite on carbon steel by gas tungsten arc welding (GTAW)

- Cladding of plain carbon steel with high chrome-high carbon electrode and evaluation of microstructure and wear behavior of clads

- Characterization of Boride Rich Hardfacing on Carbon Steel by Arc Spray and GMAW Processes

- ………..