- English

- فارسی

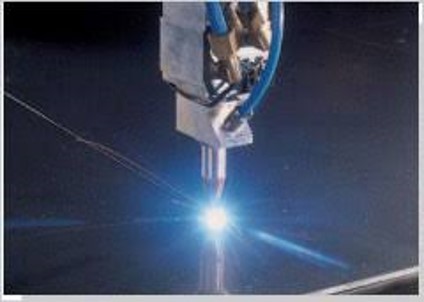

High Energy Beam Welding (Laser Welding, Electron beam welding)

Today, high-energy beams, such as laser and electron beams, have been increasingly adopted in the industry for welding, cladding, and additive manufacturing. Due to the high-energy density and small beam size, welding and additive manufacturing using high-energy beams show the characteristics of deep penetration, low heat input, small heat-affected zone, low thermal distortion, good dimensional accuracy and integrity. Here are some example of project in this area in my research group:

- Nd:YAG laser micro-welding of ultra-thin FeCo−V magnetic alloy; optimization of weld strength

- Analysis and characterization of microstructural evolutions, mechanical response and fracture mechanism of laser welded Fe–Co–V ultra-thin foils

- Structure, Texture and Magnetic Properties of Laser-Welded Ultrathin Fe–Co–V Foils

- Electron beam assisted joining of nanograin-sized FeeCoeV magnetic foils: Study and optimization of magnetic properties of weld joints

- Magnetic properties assessment of laser welded ultra-thin Fe–Co–V foils

- Response of structural and magnetic properties of ultra-thin FeCo–V foils to high-energy beam welding processes