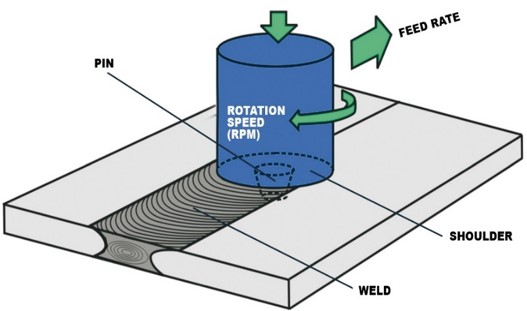

The friction stir welding (FSW) was developed in 1991 by The Welding Institute (TWI) of the United Kingdom as a solid state welding method. This welding process has many advantages in comparison with the fusion welding methods. FSP has been used to enhance the mechanical properties, wear performance and corrosion behavior of the materials. Here are some example of project in this area in my research group:

- Effect of number of passes on the corrosion behavior of Fe/Al surface composites produced by plasma spraying and friction stir processing

- Microstructure and Mechanical Properties of Dissimilar Friction Stir Spot Welding Between St37 Steel and 304 Stainless Steel

- Friction stir modification of GTA 7075-T6 Al alloy weld joints: EBSD study and microstructural evolutions

- Microstructure and mechanical properties of friction stir welded lean duplex stainless steel

- Friction-stir processing of Al–12%Si alloys: grain refinement, numerical simulation, microstructure evolution, dry sliding wear performance and hardness measurement